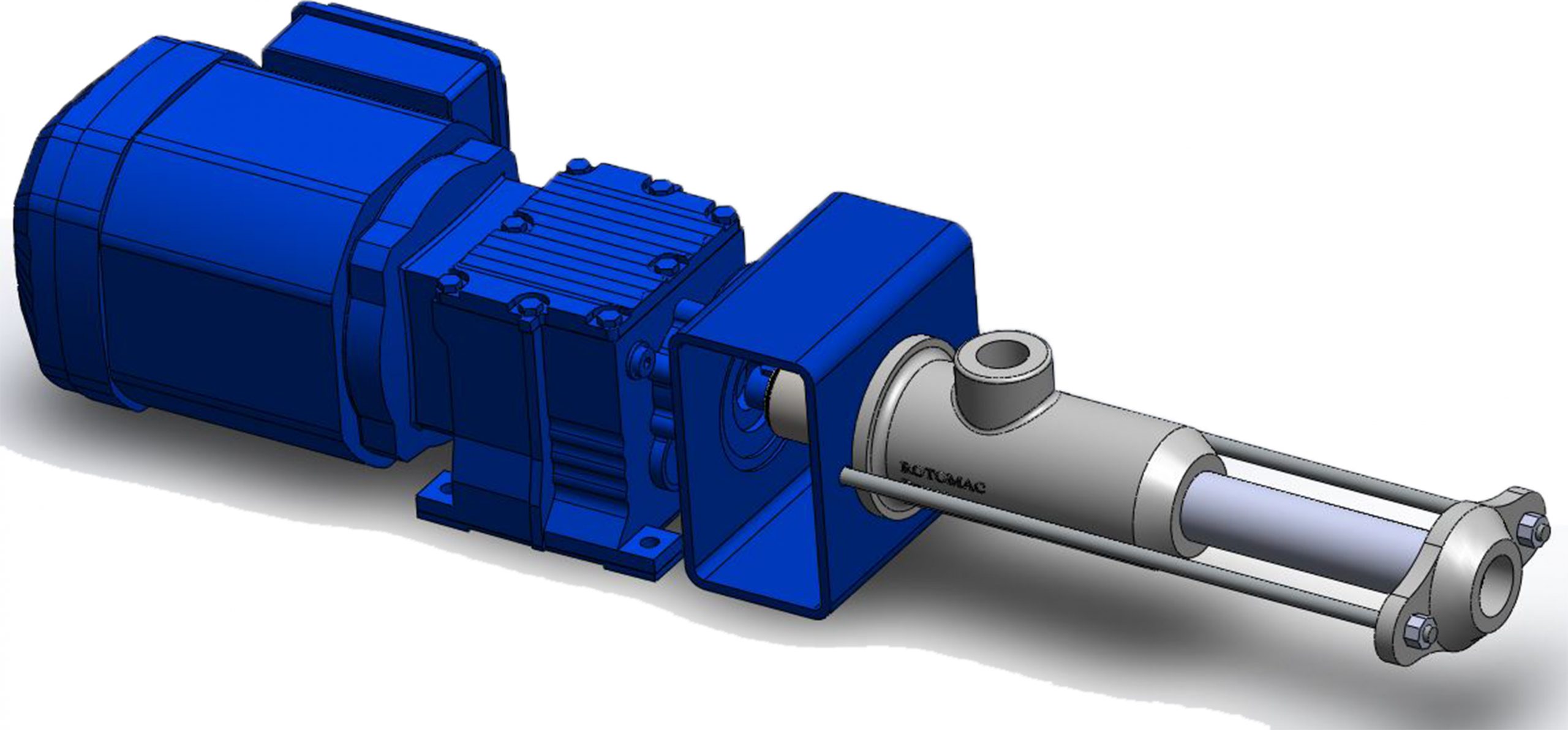

MP-LA – METERING PROGRESSIVE CAVITY PUMPS

The MP & LA Range has be designed forms the robust base of all ROTOMAC progressive cavity pumps. It can pump low-viscosity to viscous media. This range promises high accuracy and excellent repeatability .These pumps can handle the entire spectrum of fluids ranging from, clean and clear fluid to solid laden, abrasive, corrosive, highly viscous media as well.

These pump are conveying both high- and low-viscosity substances with minimal shear effect. They ensure product quality at all instances & are in-line with compliances with International Sanitary Standards.

The parts of our food and hygienic pumps are designed keeping in mind the guidelines by EHEDG principles. All materials in contact with the pumping product naturally fulfill the international requirements of the FDA and EU 1935-2004.

Features and Benefits

FLEXIBLE

Depending on the site requirements , installation can be done in a horizontal or vertical position with a large, rotatable, spherical suction intake

GENTLE CONVEYNIG

Low shear and low speed, virtually pulsation-free pumping of low to highly viscous products

REVERSIBLE

Suction and delivery ends can be interchanged by merely changing direction of rotation of the prime mover

EASY CONVERSION

Modular components for quick and easy conversion to larger or smaller sizes

LOW PULSING

Virtually pulsation free flow ad no need of dampeners and bellows

low NPSH(R), effective in high vacuum conditions.

Versatile applications

Fulfills even the strictest hygiene requirements, and is therefore suitable for numerous applications in almost any kind of industry.

High Dosing Accuracy

Offers high dosing reliability with Flow is proportional to speed so can be adjusted with ease.

MP – METERING PUMP FOR PRESICE METERING & DOSING

Designed with threaded connections for general purpose metering

Capacity: 1- 500 L /h

Pressure: ≤ 24 bar

MW – OPEN HOPPER METERING PUMP

Open Hopper pump Designed to improve Intake efficiency of High Viscous & Non-Flowable Media & robust Cardan joints

Capacity: 1- 500 L /h

Pressure: ≤ 24 bar