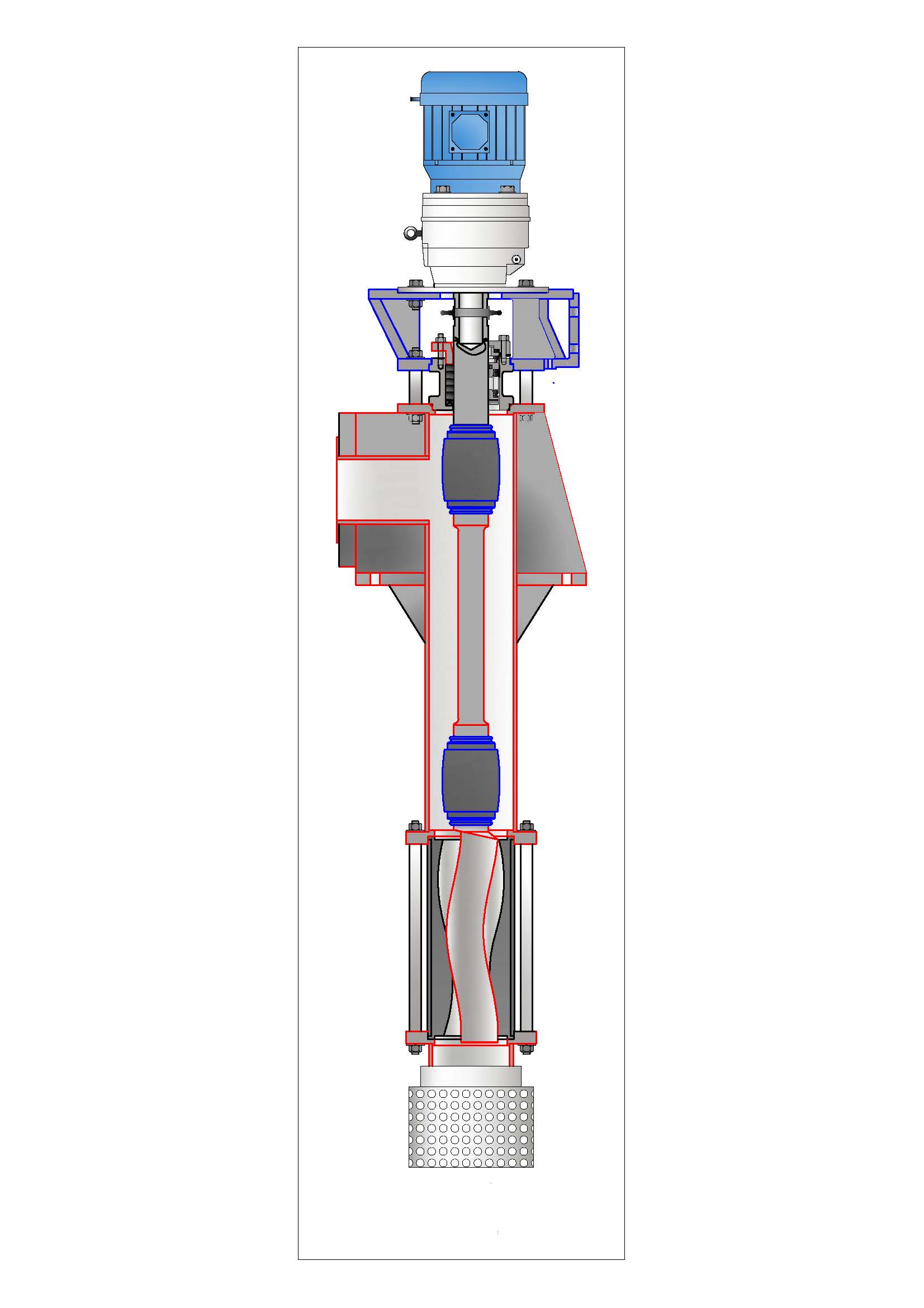

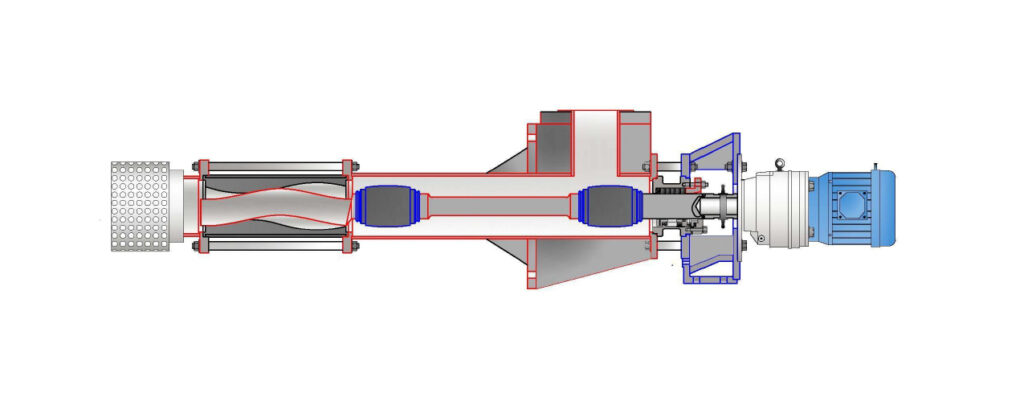

VD – VERTICAL IMMERSIBLE PC PUMPS

The VD Range is made to empty pits, basins and containers- efficiently and with ease. They can handle demanding applications such as of abrasive and corrosive media, with low to high viscosity. They are uniquely positioned to be a reliable solution to critical applications with critical suction conditions and when installation space is limited.

Capacity: Upto 80 M3/ Hr.

Pressure: ≤ 24 bar

Gentle conveying

Low-pulsation, constant flow rate for consistent product quality

More Flexible

It is possible to increase the NPSHa for liquids with low vapor pressure without cavitation – by installing the pump in a vessel

More Flexible

Suitable for installation in closed systems and compliant with environmental protection regulations thanks to its gas-tight domed lid

Different installation depths

Available in different designs for different immersion depths – all the way through to fully submersible pumps

Versatile applications

Ideal for numerous applications in the chemical industry, but also for certain conveying processes in the food, pharmaceutical and cosmetics industries

- DISCHARGE PORT:

Threaded connections to BSP standards

- ROTOR:

Wear resistant and corrosion-resistant materials. Even hardened materials are available for abrasive applications.

Conventional Geometry: Suitable for high pressure applications.

Extended Geometry : Extended Life due to larger sealing line.

- STATOR:

Available in Abrasion resistant materials as well as food-grade materials .

- UNIVERSAL JOINT

High Strength Cardan joint allows transmission of torque with minimal wear and tear. The joints are encapsulated and grease filled to protect from contamination from media. Evening case of Vacuum the joints are protected, streamlined to reduce NPHSr & turbulence.

- COUPLING ROD

Improved design for power transmission along long distances

- Pressure Casing

With connections for pressure/vacuum gauge and mounting plate for fixing the pump.

Length according to application specification.

- SHAFT SEALING:

Single-acting mechanical seal, independent of direction of rotation, with quench and supply tank to protect the sliding surface against dry running.

- DRIVE:

Geared motors, variable speed drives or frequency controlled motors of all major manufacturers, directly flanged to the pump without additional couplings or guards. Covers made of stainless steel are available

OVERPRESSURE PROTECTION

Many options are offered like Pressure Gauge Swithhces which switches off the pump as soon as the pressure reaches the pre=set pressure , and protectes the pump from damage . also we can offer a Pressure relief valve.