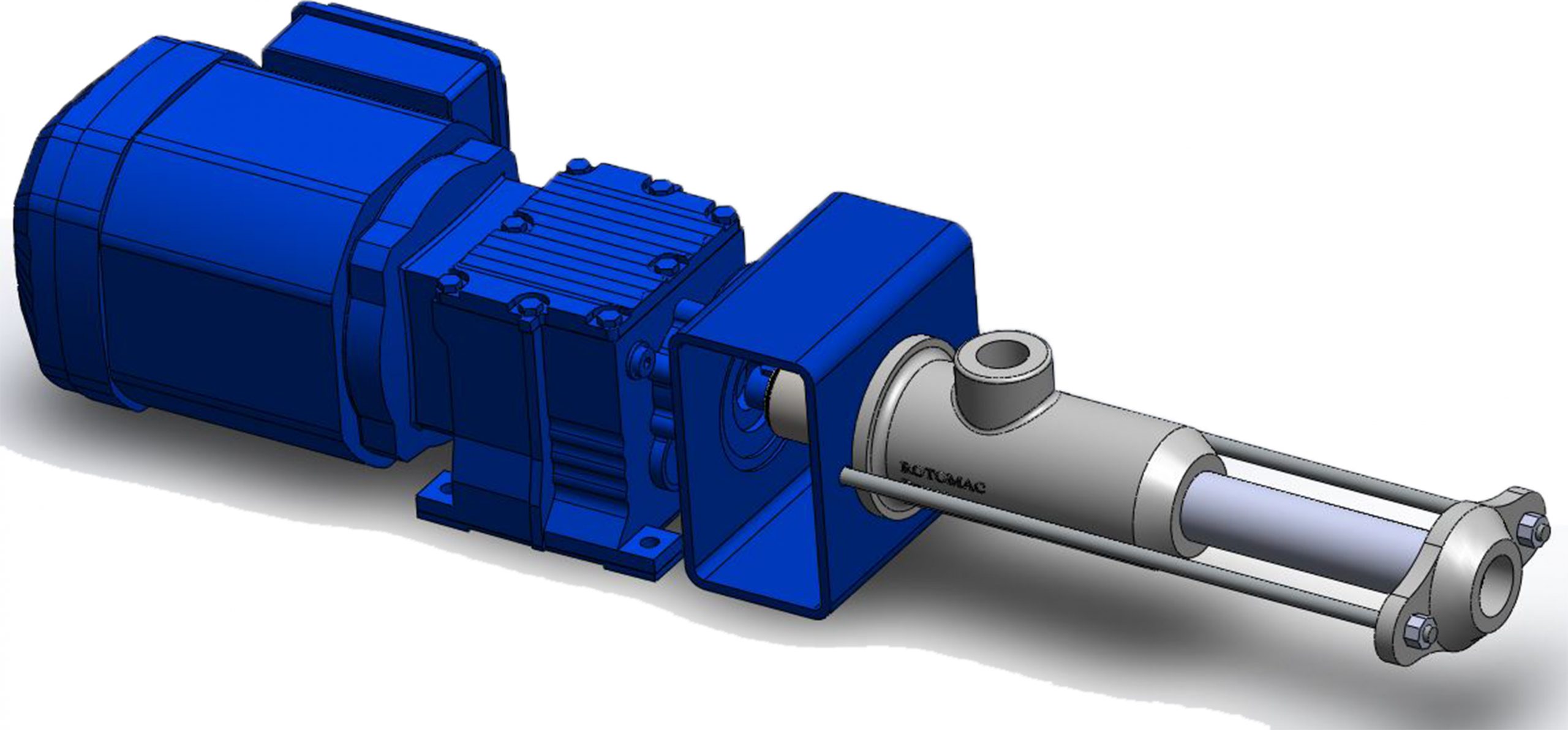

MW – Hopper Pump For Precise Metering And Dosing

Improved Intake Efficiency On Highly Viscous Media

MW range pumps are used to convey highly viscous media such as peanut butter, molasses, resins, and other media with low flowability. The open hopper on the pump directs media to the auger feed screw on the coupling rod which feeds the media into the rotor and stator

Capacity: 1–550 L/h

Pressure: ≤ 24 bar

Features and Benefits

Technology & Accessories

Features and Benefits

Economical

Reduced costs due to inexpensive rotating unit

No vapor locking

Cavity design allows for conveyance of liquids, solids, and gases

Performance Efficiency

Low slip (internal back flow) provides performance efficiency and less wear on components

Performance efficiency

Low slip (internal back flow) provides performance efficiency and less wear on components

Ease of Operation

Valveless flow control for ease of operation

Technology & Accessories

- Discharge Port:

Only available In stainless steel, Threaded connections to BSP or NPT standards

- Rotor:

Wear resistant and corrosion-resistant materials.

- Stator:

The seal on both ends is molded as an integral part of the elastomeric stator.

- Open Hopper:

Rectangular Feed Hopper with conveying screw for pumping highly viscous product .

- Coupling Rod:

With two pin joints with hardened and wear resistant components, easily assembled, grease lubricated and positively sealed with elastomer sleeves and two holding bands.

- Shaft Sealing:

Only available with Mechanical seal configurations

- Close Coupled Drive Connection:

For easy dismantling of the pump and drive enabling quick replacement of the rotating parts and shaft seals. The yoke shaft pin secures the shaft connection to the drive and the Water Thrower protects the drive from contamination/gland leakage.

- Body:

For connection of pump and drive and to secure the assembly to the baseplate or directly to the foundation.

- Drive:

Geared motors, variable speed drives or frequency controlled motors of all major manufacturers, directly flanged to the pump without additional couplings or guards. Covers made of stainless steel are available